Pete has been flying aircraft for the last 20 years. He has flown everything from light piston aircraft up to heavy jets as both First Officer and Captain. He’s currently enjoying life flying the Airbus A330 for a major international airline.

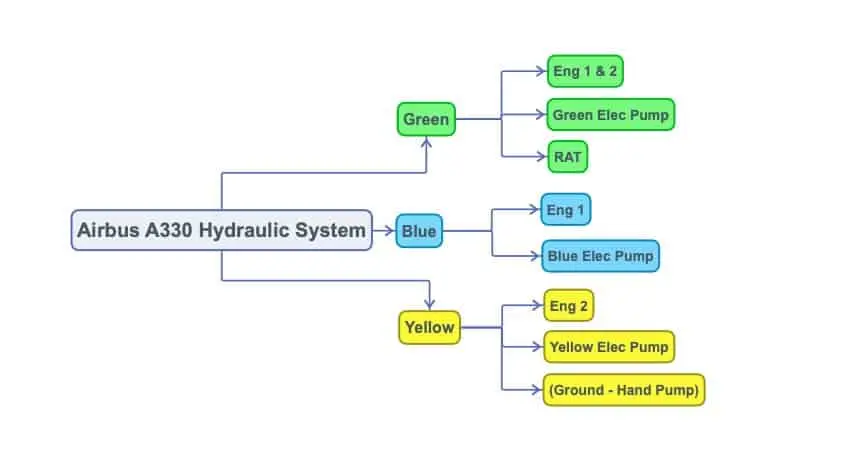

The Airbus A330 hydraulic system is comprised of three independent systems that operate continually to power the flight controls and various systems including the landing gear, brakes, nose wheel steering and the emergency electrical generator (EMER GEN).

Table of Contents

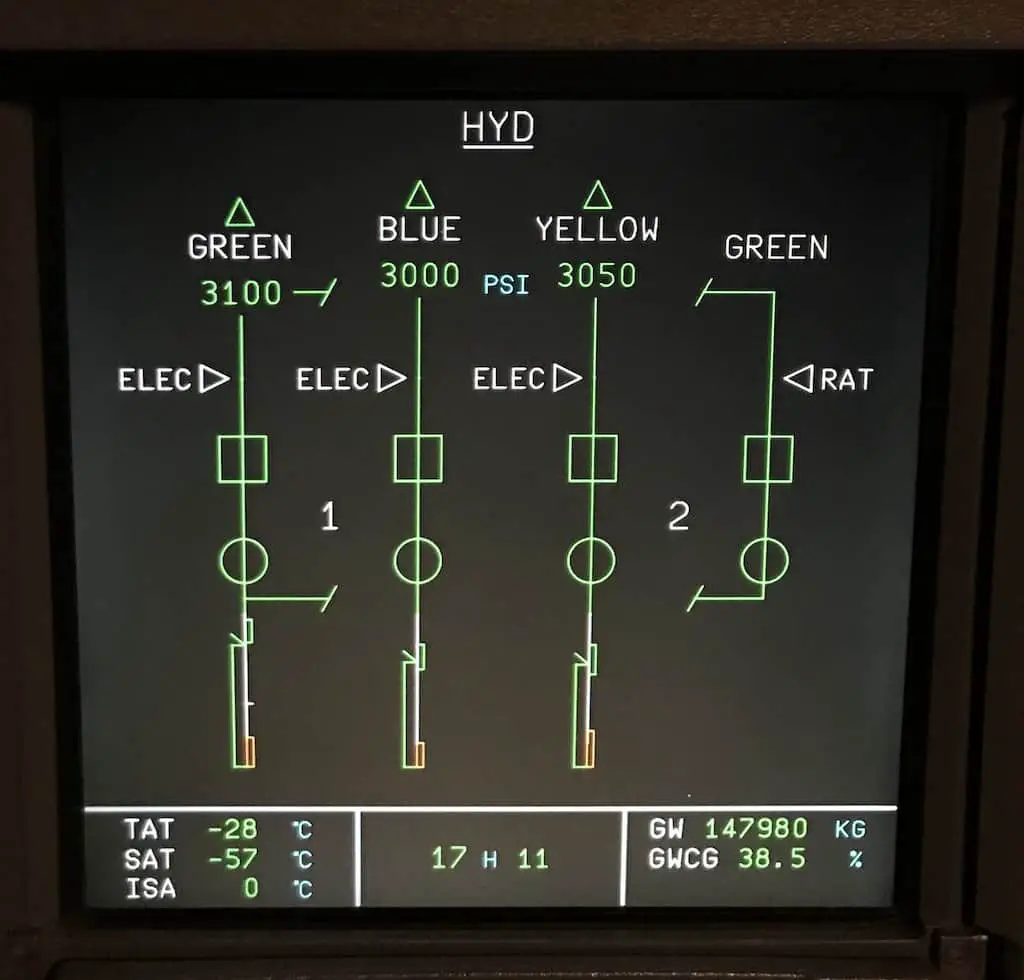

The Green, Blue and Yellow hydraulic systems each have their own resevoir and are supplied with a normal system pressure of 3000psi by engine driven pumps (EDPs).

Each system (green, blue and yellow) also has its own backup electrical pump which can supply pressure in the event of EDP failure or engine failure.

Note however that the flow from an electrical pump is significantly less than from an engine-driven pump:

…the electric pump flow is about 18% of the engine-drive pump flow capacity, It can be used to retract the surfaces, but should not be used to replace the engine-driven pumps.

Airbus A330/A340 Flight Crew Operating Manual (FCOM)

The green system is further backed up by a Ram Air Turbine (RAT) which can supply hydraulic pressure to vital systems in the event of a serious electrical failure or a loss of both engines.

In the event of hydraulic pressure being supplied by the RAT the pressure is reduced to 2500psi.

A Hydraulic System Monitoring Unit (HSMU) monitors the system for faults and displays them on ECAM (Electronic Aircraft Centralized Monitor). The HSMU also controls the electric pumps, fire shutoff valves, leak measurement valves and the RAT extension in an emergency.

A schematic of the hydraulic system layout and components can be found in the Quick Reference Handbook (QRH) in the cockpit to aid in trouble shooting problems.

The ECAM (Electronic Centralized Monitoring) system will also provide warnings to the pilots and checklists to deal with any emergency situations.

Related: A Guide to ECAM and EICAS Systems

A330 Green Hydraulic System

Under normal circumstances, green hydraulic pressure on the A330 is supplied by engine driven pumps (EDPs) – one in each engine.

The green hydraulic system can also be supplied by the green electric pump.

In an emergency the green system can be pressurized by the Ram Air Turbine (RAT). The RAT is a small propellor that can be deployed manually by pressing the RAT MAN ON on the overhead panel. The RAT also deploys automatically in the event of a loss of both engines or low hydraulic fluid level in the green and yellow, or green and blue, reservoirs.

If this is the case the available green hydraulic pressure is 2500psi. This is due to the fact the RAT flow varies with air speed and only supplies between 15-45% of the pressure that would be supplied by an engine-driven pump.

Related: A Guide to the Ram Air Turbine (RAT)

Systems Powered by Green Hydraulics

- Emergency Electrical Generator (EMER GEN)

- Nose Wheel Steering (NWS)

- Landing Gear

- Normal Braking

- Flaps & Slats

- Flap & Slat Wing Tip Brakes (WTB)

- Yaw Damper 1

- Spoilers 1 & 5

- Inboard & Outboard Aileron

- Lefthand & Righthand Elevator

- Rudder

A330 Blue Hydraulic System

Main blue hydraulic pressure on the A330 is supplied by an engine driven pump on engine number 1 (EDP 1).

Backup hydraulic supply to the blue system is by means of the blue electrical pump.

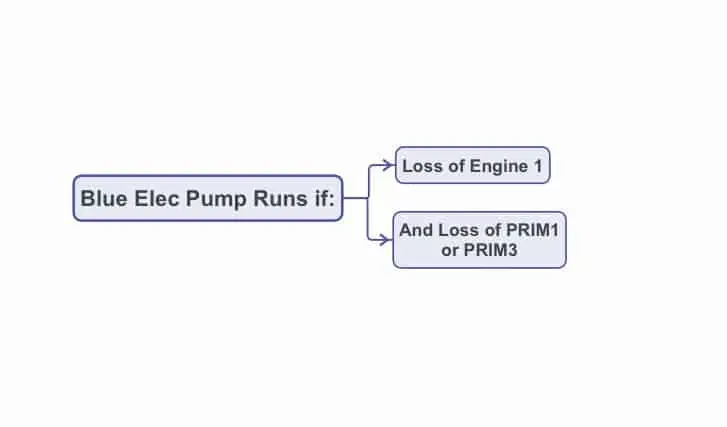

Blue Electric Pump

The blue electric pump (BLUE ELEC PUMP) can also pressurize the blue hydraulic system. The blue electric pump can be selected on manually on the overhead panel.

The blue pump will also operate automatically in the event of an engine one failure, together with the loss of PRIM 1 or PRIM 3 (Flight Control Primary Computers) – this is to ensure sufficient control authority is available on the electrical rudder (if installed) to counteract the yaw created by the engine failure.

Systems Powered by Blue Hydraulics

- Alternate Braking

- Parking Brake

- Slats

- Slats Wing Tip Brakes (WTB)

- Pitch Trim 2

- Backup Yaw Damper Unit (BYDU)

- Spoilers 2 & 3

- Inboard Aileron

- Lefthand Elevator

- Rudder

A330 Yellow Hydraulic System

The yellow hydraulic system on the Airbus A330 is powered by an engine-drive pump (EDP) in Engine 2.

There are also an electric pump and a hand pump able to supply the yellow system with pressure.

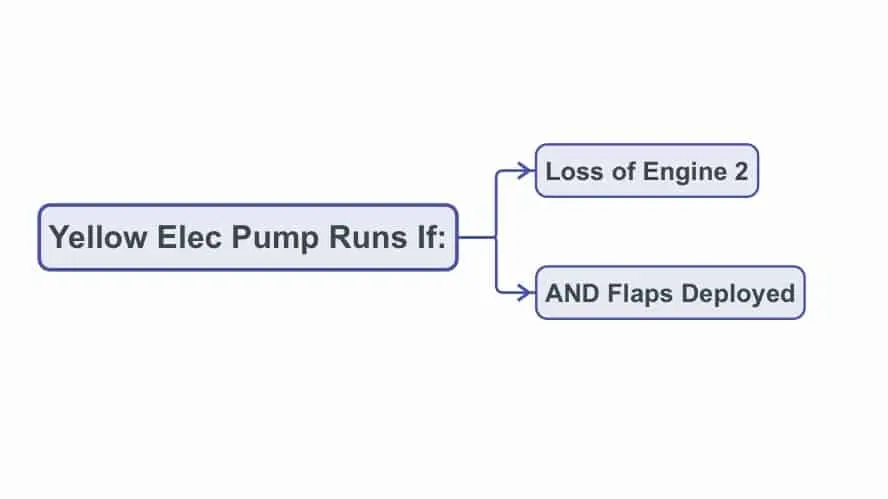

Yellow Electric Pump

The yellow electric pump can be manually selected to run by a switch on the overhead panel. It will also run automatically in either of the following situations:

- with a failure of Engine 2 in flight, and with the flap level not set to 0. The pump runs to ensure flap retraction in proper time if the engine failures during take off.

- on the ground the pump will run when the cargo doors are operated by the ground crew.

The hand pump can be used by the ground crew to operate the cargo doors when there is no electrical connection available to run the electrical pump.

Systems Powered by Yellow Hydraulics

- Flaps

- Flaps Wing Tip Brakes (WTB)

- Pitch Trim 1

- Yaw Damper 2

- Backup Yaw Damper Unit (BYDU)

- Spoilers 4 & 6

- Outboard Aileron

- Righthand Elevator

- Rudder

Hydraulic Failures on the A330

AS you can see from above, the Airbus A330 has very significant backups built in to the hydraulic system.

The loss of a single hydraulic system on the A330 will result in very minor issues. The A330 will still be able to auto land, albeit to CAT 3 SINGLE (downgraded from CAT 3 DUAL).

Single hydraulic failures have very little effect on the handling of the aircraft but will cause a degradation of the landing capability to CAT 3 SINGLE.

Airbus A330/A340 Flight Crew Techniques Manual

The loss of two hydraulic systems, although very rare, has significant implications for the flight.

With a dual hydraulic failure on the A330 the pilots will still be able to the aircraft but without the use of autopilot. Flight directors (FD) and auto thrust (A/THR) will still be available.

The flight control law is degraded and there will be numerous ECAM procedures to complete. The loss of two hydraulic systems and the resultant loss of those components (e.g. spoilers, normal braking, flaps etc.) will result in a significant increase the landing distance required (LDR) which can be derived from the performance section of the QRH.

“…dual hydraulic failures, although unlikely, are significant…”

Airbus A330/A340 Flight Crew Techniques Manual

For more on what happens when aircraft lose hydraulics (and fuel!), take a look at:

What Happens When Aircraft Run Out Of Fuel

A Guide to the Airbus A320 Hydraulic System

Related reading: Airbus Safety First – A320 Dual Hydraulic Failure

If you found this article interesting please take 5 seconds to share this on your favorite social media. Thanks so much, I really appreciate it! [email protected]

Pete has been flying aircraft for the last 20 years. He has flown everything from light piston aircraft up to heavy jets as both First Officer and Captain. He’s currently enjoying life flying the Airbus A330 for a major international airline.